Trailer Tech: U-bolt and tie plate torque and tightening, understanding the critical sequence.

Welcome back to Trailer Tech!

We’d like to go over some tips and installation guidelines when it comes to torquing and tightening down your tie plates, to ensure your kit installation goes as precisely and smoothly as possible.

The proper tool is critical to any job and we highly recommend the use of a torque wrench equipped with a dial indicator. A low quality click-style torque wrench can be “tricked” into overtorquing stretch bolts as some wrenches require the desired torque to be realized abruptly in order to force the click. When torquing stretch hardware such as u-bolts and tie plates, the desired torque is stretched slowly from the bolts onto the plates – often too slowly to force a click on a click style torque wrench. Installing u-bolts and tie plates without accurate data can easily lead to over / under torquing. To avoid this, use a high quality click style or dial indicating torque wrench during the installation and remember to tighten the bolts at a slow, incremental pace. Adhere to the specific torque specifications listed on the informational stuffer provided with your order.

It’s also important to observe use of a tightening sequence when torquing down the bolts. Doing so can have a major impact on the kit’s long-term functionality. The main factor is the reduction of uneven strain on the tie plates and shaft deflection on the U-bolts. Bolt tightening sequence can have a major influence on the preload generated in the bolts and the resulting clamping force that keeps the axle and spring assembly together.

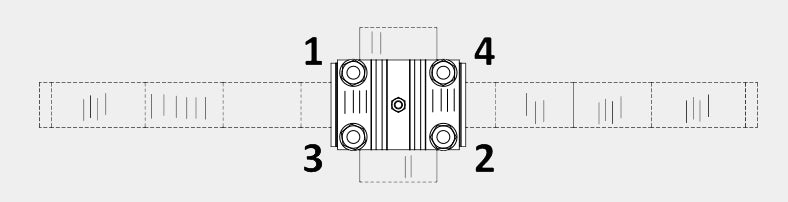

The correct tightening sequence is depicted below:

Begin with hand assembly and repeat the sequence through a second and third tightening stage until the correct torque setting is achieved using the wrench.

As always, we recommend you consult with a qualified mechanic with experience servicing trailers whenever you have any doubt as to the correct way to proceed. Always consult your trailer owner’s manual for more information. We hope you find this article useful when executing assembly of your kit. If you have any additional comments and queries, please leave a message below or reach out to us on our various social media channels.

Thanks for reading!